- Call Us.: (+91) 9871874911, (+91) 98111 25258

- Email us: info@tephrapolymers.com

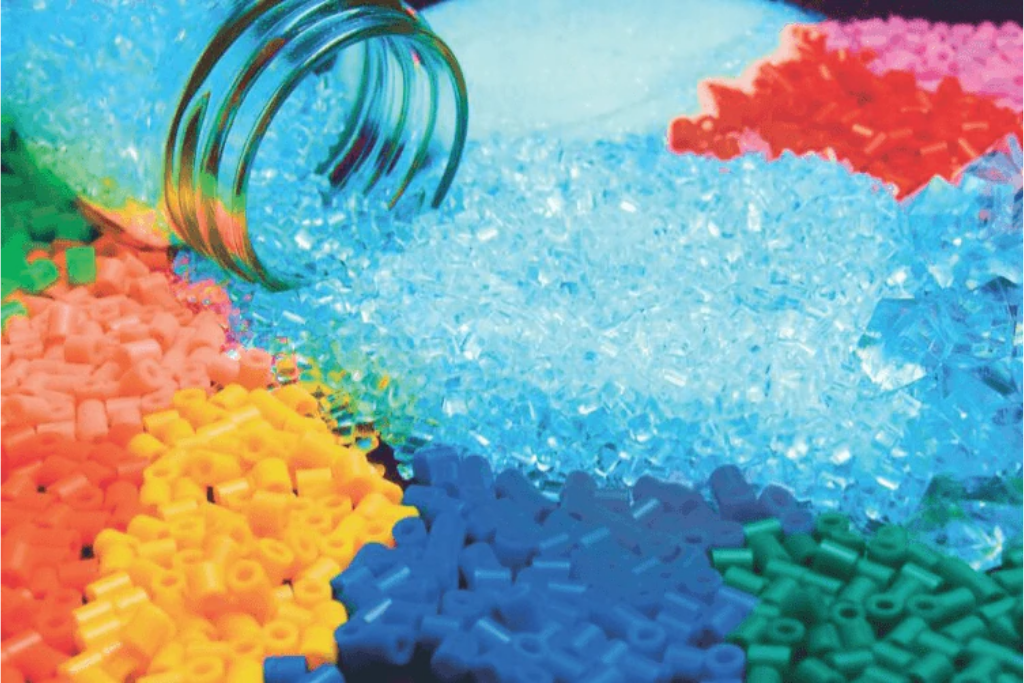

OUR PRODUCTS

Quality Material

Our product line stands tall on each and every requirement of esteemed clients because of being produced rightly using quality base materials

Master Batch Industry

Tephra Polymers is eminent Plastic Masterbatch Manufacturer In India. Tephra Polymers successfully fulfilled requirements by providing best quality Plastic Master batch and has achieved a leading position in plastic master batch industry

Shipment Process

Master Batch are tested on several quality parameters prior the process of shipment. Stringent testing of products ensures delivery of singularly quality-approved products

Tephra Polymers Growth in Master Batch Industry, India

Tephra Polymers master batch industry growth, we stick to our small company way of doing business by way of our flexibility, personalized and responsive service and ability to provide specific solutions for each customer’s requirements for master batch.

MASTERBATCH

is used to improve the property of polymer to offer better-finished products. Additive Masterbatch is segmented into seven sub types, namely, antimicrobial, antioxidant, flame retardant, optical brightener, and nucleating agent.

Colour MB (Master Batch) we produce almost all Colour Masterbatch in economic & regular grades even filler free specialized colour master batches also produce by Tephra Polymers.

White Masterbatch, also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging and labeling, textiles (e.g., ropes, thermal underwear and carpets), stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes.

Black Masterbatch, also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging and labeling, textiles (e.g., ropes, thermal underwear and carpets), stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes.

COMPOUNDS

Polypropylene (PP) Master Batch, also known as polypropene, is a thermoplastic polymer used in a wide variation of applications including packaging and labeling, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes. An addition polymer made from the monomer propylene, it is rugged and unusually resistant to many chemical solvents, bases and acids.

ABS master batch stands for Acrylo Nitrile Butadyne Styrene granules. Their chemical composition render them the physical properties like hardness, rigidity and the tendency to remain tough even at low temperatures. These ABS Granules consist of particles of a rubber like toughener suspended in a continuous phase of styrene acrylo nitrile (SAN) copolymer.

fILLER

Talc filler (tpt filler ) is 75% 2-micron talc filled LLDPE or PP concentrate. Increases stiffness, density and temperature resistance of polyolefin resins. Allows increased heat conductivity and higher output in film and sheet extrusion process. Serves as anti-block and smoother surface modifier. Its Improves the Flow Properties and Strength, stiffness, Whiteness &Transparency of the final product.

Our calcium carbonate filler master batch is best suitable for multilayer films, mono layer film extrusion, woven sack, non-woven fabric, and pefilms.

Desicant Filler

Desicant moisture removal additives and master batch is one shot solution for blown films extrusion injection molding other and other processing to ensure good quality yield reduce energy consumption and improve productivity. it can be used in PP, PE, LDPE, LLDPE, HDPE, HIPS, EVA, PVC, BIODEGRADABLE, PIPES, FILMS, TUBES, SHEETS, etc. Plastic and other plastic compounds.

Satisfied Customers