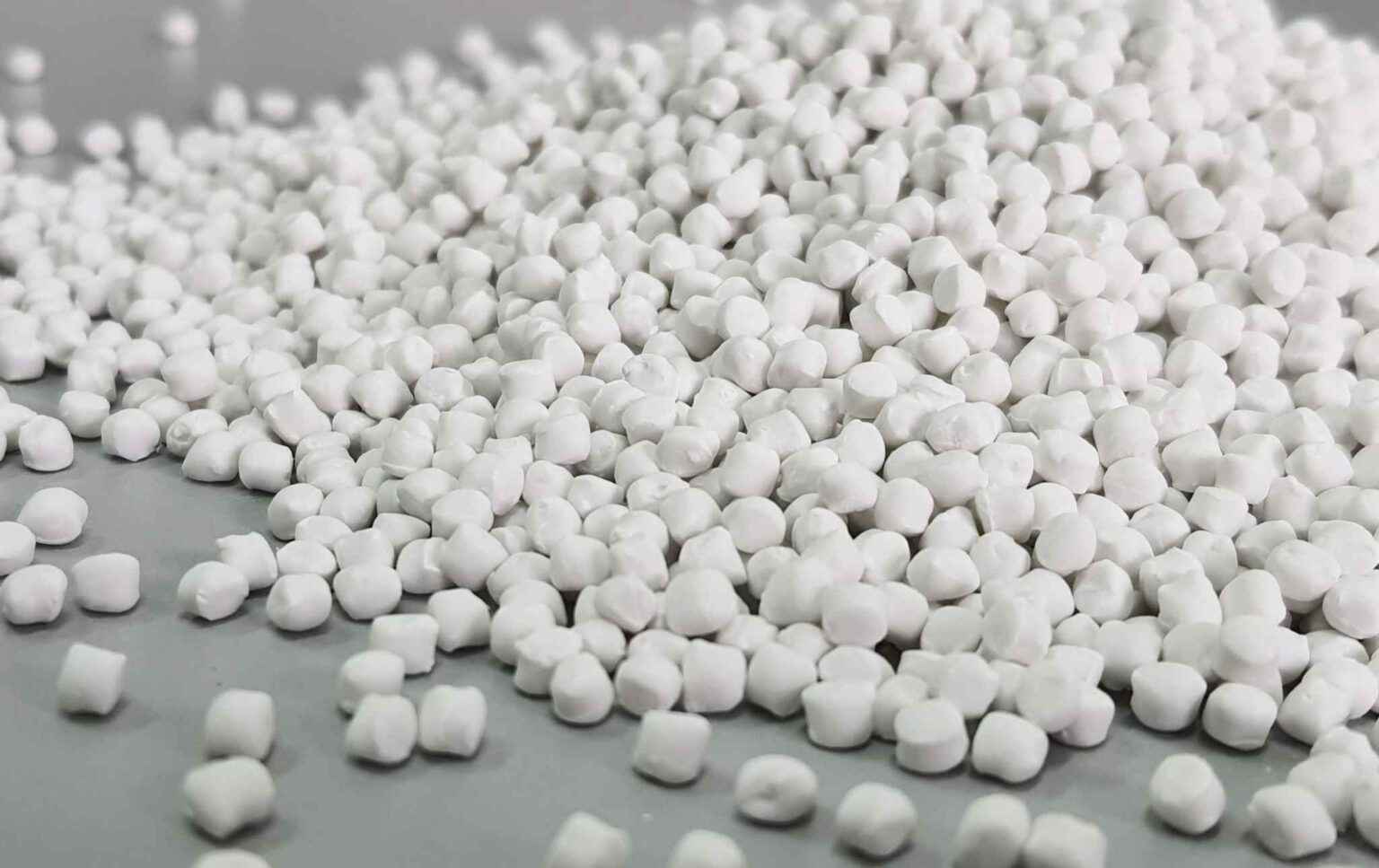

Tephra Polymers Masterbatch Manufacturer in Delhi is made of Talc powder – an indispensable ingredient

Talc filler Masterbatch Manufacturer in India is a assortment made of talc powder, base resin (PP, PE, HD, HIPS, etc.) and different additives such as dispersant additives, bonding additives, etc.

So what is Talc powder? Talc is a metamorphic mineral in solid form. The full scientific name is hydrated magnesium silicate, with the chemical formula is Mg3Si4O10(OH)2. In nature, talc is often found in a stone called steatite or soapstone (a high-talc rock), it is often combined with other minerals such as chloride and carbonate. Talc is usually blue, white, gray, brown or colorless.

In various plastic Masterbatch Manufacturer in India ranging from plastics, cosmetics, paper, etc. talc is ground into white powder and mixed with other multiple compound so it is known as talcum powder. In addition, talc is also known as “soft stone”. This stone, as its name suggests, has a special softness that is often used in sculpture.

It can be said, thanks to the following 4 excellent features, “talcum powder” has very special properties that are generally applied in different fields:

Moderate softness (Talc has the lowest hardness compared to other minerals in nature)

-

It’s very smooth and feel like a soap when you touch

-

Good in electrical insulation, good insulation, high melting point, low thermal expansion

-

Force with organic substances (capable of combining with organic substances)

-

Is an inert chemical

In the plastic Masterbatch Manufacturer and Supplier, Talc is widely used by masterbatch manufacturer in Delhi to produce filler masterbatch. As a high-content ingredient in plastic fillers, talc will increase the hardness of several base resins such as polypropylene, vinyl, plastic, nylon and polyester. Moreover, it can also function as an anti-stick agent, antifreeze, lubricant, smoothing agent, etc.

The role of Talc filler Masterbatch Manufacturer in India

Talc filler Masterbatch Manufacturer in India is composed of talc powder, base resin and supportive additives. It is measured as the perfect filler for plastic that help Masterbatch Manufacturer in India improving production while reducing production costs. Plastic masterbatch contain talc powder can be used to change a part of primary plastic (the input material for plastic-based products manufacturer). This is a smart solution aiming at saving raw materials while limiting the amount of crude oil – resources are increasingly done in plastic production. Another great result is that the talc filler will greatly improve the plastic properties, help the plastic output products have higher value in the plastic materbatch consumer market.

Masterbatch Manufacturer and Supplier

Talc is an all-purpose inexpensive filler powder for all resin types for creating a cheap but heavy gap filler for the masterbatch industry. Also used in resin casting to reduce cost, shrinkage & heat generated by resin curing. The more filler added to resin the stiffer the mix.

Since it is a common product plastic with low weight and density, its use may be limited without the plastic fillers and additives that make it more essential. One such plastic filler/additive is talc, a water-repellent, a chemically inert mineral comprising of a layer or sheet of brucite sandwiched between two sheets of silica.

If you are looking for a master batch manufacturer in India & not worried about price & care for quality of raw material granules then go with Tephra Polymers. we are very stratified with this company.

Mahesh Agarwal, Customer

I’m always impressed with the Tephra Polymers Master Batch manufacturer in India. company have Excellent master batch product quality. Any person who is looking for a raw material plastic granules or master batch which fulfill yours industrial requirements with high quality value should connect Tephra Polymers.

Kaushal Singh, Customer

We are delighted with the outstanding quality of Tephra Polymers master batch, Thank you so much. We connect with this since 2015 .Tephra Polymers are the best manufacturer of plastic master batch in India. I will definitely recommend for high quality master batch.

Anand Pal, Customer

We are extremely happy that we chose to Tephra Polymers master batch manufacturer. They best quality of plastic granules. I can honestly say that this was my first plastic granules manufacturer that went smoothly and on time.

Rahul Walia, Customer